Optimal position of the hood

|

Local extraction is first of all a matter of eliminating the pollution effectively and achieving optimum efficiency. There are three simple rules you should follow:

1. Position the hood correctly in relation to the pollution source.2. Choose the right hood. 3. Be as close to the pollution source as possible. 1. Position of the hood

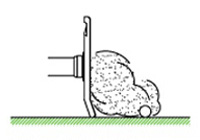

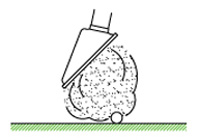

You can arrange the position of the hoods in three groups; the horizontal, the vertical and the angled position of the opening of the hood. (Fig. 2-4). Many users place the opening in the horizontal position which is mostly the less efficient position. It is important that you consider the optimal position of the hood before you choose the hood, because the various types of hoods are suitable in various positions.

The dispersion characteristics are essential for the position of the hood. There are many types of pollution with different dispersion characteristics such as swirling dust, hot steam, soldering and heavy gasses.

The vertical and the angled positions are in general more efficient than the horizontal position as they both and especially the vertical position gets a stronger capture efficiency to the nearby horizontal surface. The horizontal position is however less efficient. You will find more information in our test report on capture efficiency.

Example 1:

A heavy gas that is evaporating quietly will lie down on a flat surface (table) and spread over it. In this case, the optimal position will be with the opening of the hood placed vertically placed against the table.

Example 2:

However, a warm vapour rises upwards with some velocity. In this example an angled position of the opening above and possibly slightly behind the pollution source will be preferable.

Both examples lead to the choice of two different types of hood.

2. Choice of hood

The individual types of hood can be recommended for one, often two of the three options. Generally, we say that the dome hoods are well suitable in the angled or horizontal position, whereas the flat screen is best in a vertical or an angled position. Due to the design, the square hood can be placed naturally in all three positions, but you obtain the highest efficiency by the vertical and the angled position. See more information about the position of the individual hoods under the overview of the individual systems. Example 1 - continued:

Several hoods are suitable for the position of the vertical opening for heavy gasses.The precise hood depends on the system (50, 63, 75 or 100). But the flat screen is available in all four systems and is designed for a vertical opening and a position on or near to a horizontal surface (table). By this positon the flat screen will build a drag over the table which will direct the heavy gas to the screen.

Example 2 - continued

There are also several other hoods suitable for the angled position of the opening in connection to hot steam; among others the flat screen; but due to the position and the pollution, a dome hood could be a better choice. The size of the dome hood depends on the size of the pollution source.

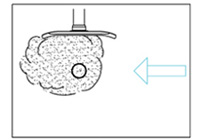

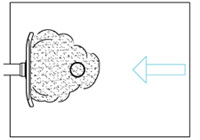

3. Distance and cross-flows

The extraction efficiency also depends a lot on the distance to the pollution source and the movements of the surrounding air. This means that, the closer the hood is placed to the pollution source, the higher efficiency.

Then it is advantageous to place the hood in the direction that the pollution moves. Examble. If a cross-flow in the room eg cold air from a window over the table leads the pollution in a certain direction, you place the hood in order to take advantage of the direction and the speed of the pollution (Fig. 5-6).

|

|